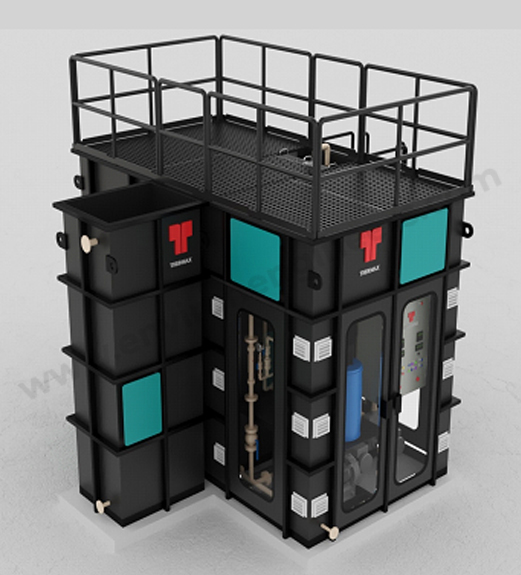

This technology with lower footprint is a better alternative to conventional wastewater treatment plants with larger capacities, which require monitoring at multiple points. It works on improved FAB (Fluidised Aerobic Bioreactor Technology) based technology and offers an effective option to the conventional systems made unavailable due to scarcity of open space, geographical network of piping, high power and land cost.

Salient Features

- Skid mounted for quick and easy installation

- Self-regulating system

- Pre-engineered for low cost and fast delivery

- Achieves <5 TSS mg/l without PAC+ PE dosing

- Achieves <5 BOD mg/l without using UF membranes

Standard capacities

- Prefabricated : 50,75 and 100 KLD (modular for other capacities)

- On-site fabrication : 10 to 5000 KLD